Dry Sap

Container Desiccant

Cargo Dry Solutions

Topsorb is expert of container desiccants, provide perfect cargo dry solutions. Our container desiccant bags create a dry environment in the container, protecting your valuable goods from humidity damage. It can effectively adsorb humidity, and control “dew point” temperature below the actual temperature, and thus prevent mildew, rust formation.

DRY SAP-125G,500G,750G,1000G:

Tyvek packaged, the back side is with adhesive function,hook optional.It can be pasted onto the pallets or cartons to avoid “Cargo Sweat”.

Absorbent: CaCl2+water adsorption material; Adsorption capacity: 280%~300%

Specification Sheet

| Specification | Pack Size (mm) |

Net Weight (g) |

Packing Qty(pcs/ctn) |

| Dry Sap-125 | 150*210 | 125 | 48 |

| Dry Sap-500 | 150*840 | 500 | 12 |

| Dry Sap-750 | 150*1260 | 750 | 8 |

| Dry Sap-1000 | 150*1680 | 1000 | 6 |

Glue on the rear

Absorption Capacity

Dry Sap absorb over 300% in full performance at 90%RH.

It provides perfect solution to prevent the goods in containers from moisture damage.

Super Adsorption Capacity

Solid gel & Anti-leakage

Topsorb VS Other CaCl2 powder desiccant

Topsorb developed unique formula of absorbents, which is quite different from the other desiccant suppliers, not matter in physical appearance, or in adsorption performance.

First, it has stronger adsorption capacity over 280%~300%.

Second, fantastically, in the whole process of absorbing,the absorbent remains in solid form , no single minute turn into liquid form, from the beginning, to the full working conditions, until being saturated,

It entirely prevents the risk of liquid leakage.

Most desiccant products on the current market, the CaCl2 powders inside sachets turns into entire liquid when the adsorption reaches 60%~80%. This state of being liquid lasts several days or even longer (depending on the temperature & humidity conditions) , then it slowly turns into gel.

It is a high-risk period when the absorbent remains in liquid. When the desiccant sachets are squeezed or pressed during transport or operation, the joint of sealing part has a risk to be cracked and damaged. As a result, the leakage occurs from the inside liquid,and then the customers’ goods is polluted by the leakage.

Package Picture

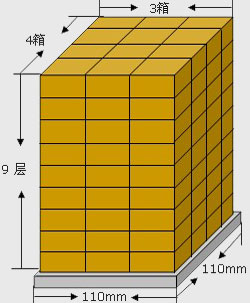

Loading Drawing

Shelf Life

24 months from production date(under the right store and unabroken circumstance)

Usage instruction

1. Check whether the conatiner is damaged,whether there is a hole or crack on the container wall,the top and bottom.Container doors can be closed tightly and the seal must be good.The container must be dry and clean before loading.2. Inspeciton of container wood floor.if possible,do not use containers with wood floor humidity over 20%,it would increase the risk of damp.

3. Seal all air-wents on the container wall.Very important!

Desiccant plays an effective role only in a closed enviroment.If the container door is not shut tightly, or there is damage on the container or the air-vents inside are not sealed,desiccant will never be able to absorp up the mositure that continually enteres from outside.

4. Hang Dry Sap and recommended dosage:Open the package and hang dry paste up to the iron hoop on the container wall,as shown in the picture,Use 40bags~48bags per 20’ container,80bags~96bags per 40’ container.For professional advice of desiccant dosage,please contact Topsorb.

Chinese

Chinese English

English